Jun 16, 2021 “Four additional special levels, S-1, S-2, S-3 and S-4 may be used where relatively small sample sizes are necessary and larger sampling risks can be tolerated” (ISO 2859-1 standard). Under S-3 level, the number of samples to check is lower than under S-4, and so on. You have to enable javascript in your browser to use an application built with Vaadin. ISO 17078-3:2009(en), Petroleum and natural gas industries — Drilling.

The Acceptance Quality Limit (AQL) is a proven statistical instrument at the disposal for quality control when it comes to evaluating product quality.

The need for quality control

In virtually every production batch, there will be defective products - however they could be extremely rare. There will always be defective products even after the QC has checked and repaired each individual product. Flawless products only exist in a perfect world, the goal is to create products that are within acceptable tolerances. Although the quality assurance systems of manufacturers of primary packaging materials are becoming increasingly more efficient through the use of innovative technologies, such as electronics and laser refraction modules, there will always be room for improvement and there are always ways to make it even better; each production run is another opportunity to create new quality standards. Notwithstanding the fact that a buyer always want a zero defect product, the supplier cannot be expected to deliver absolute zero defect goods. However, the buyer wants to control the consistent quality of purchased goods, since it does not want (too many) defects.

AQL background

Not each and every individual product can be fully checked as to its functionality. Products would become highly expensive or even instantly obsolete, as destructive test methods would destroy the product. For this reason acceptance sampling has been developed. Acceptance sampling is a statistical quality control instrument that represents a compromise between doing no inspection and a full inspection. Acceptance sampling originated way back, even before the Second World War, when the US military had to determine which batches of ammunition to accept and which bullets to reject by a destructive test method. The US army therefore developed the Military Standard 105-D, testing a few representative bullets from the production batch so they could trust the other bullets would perform on the battle field. Ultimately this might mean the difference between life and death.

The sampling scheme by which representative samples (sample rate) are selected from a population (production batch/lot) and tested to determine whether a production batch/lot is acceptable or has to be rejected is known as an acceptance plan or sampling plan administrated??? according to DIN ISO 2859 part 1. Hence the AQL, defined as the quality level that is the lowest acceptable, is a statistical procedure for determining production batch/lot quality.

AQL standard for moulded glass

Primary packaging materials made of moulded glass for pharmaceutical and cosmetic purposes are often manufactured according to quality agreements based on the 'Defect Evaluation List for Containers Made of Moulded Glass' and to the appropriate GMP Rules of the WHO (see 'Editio Cantor' )

Acceptable defect level:

Om het maximum aantal ondeugdelijke eenheden (het acceptabele aantal ondeugdelijke producten) te bepalen, moet een kwaliteitsinspecteur weten:

- The production batch/lot size

- The inspection level

- The random sample size

- The AQL portion

To determine the correct sampling plan and acceptance/rejection level, quality inspectors rely on basically two AQL tables:

- The first table determines which 'code letter' to use based on the inspection level and production batch/lot size.

- The second table determines the sample size and maximum number of defects that can be accepted based on the code letter and AQL.

General inspection level II is the most widely acceptable level for moulded glass bottles.

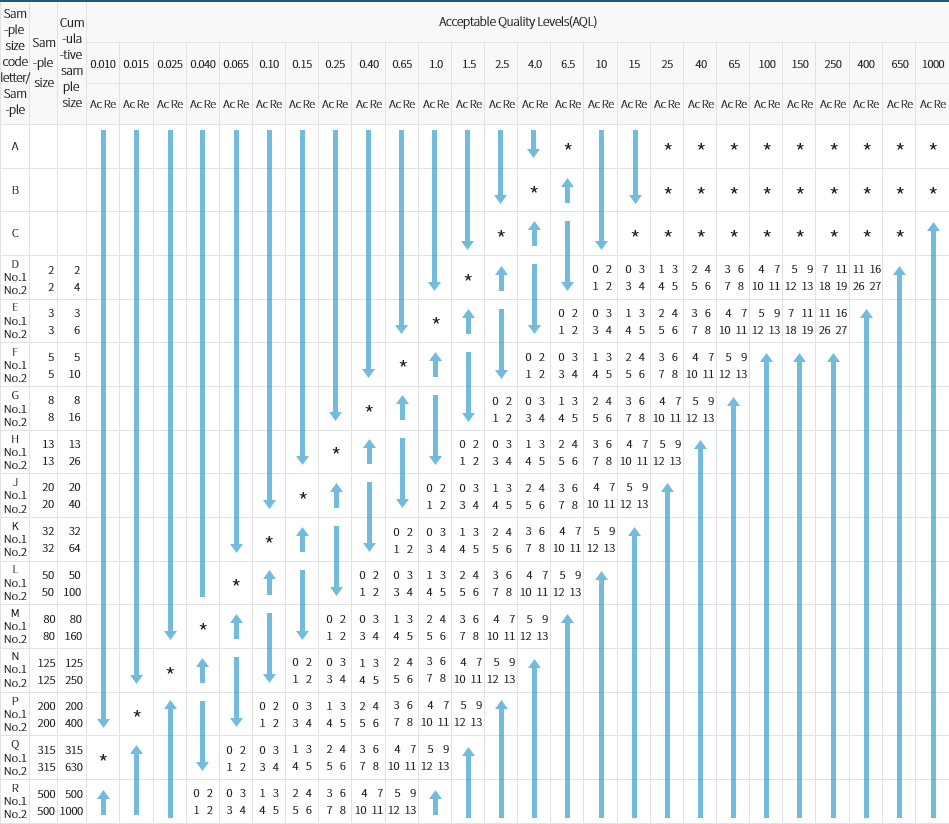

Table 2 -Single sample plans for normal inspection according DIN ISO 2859-1

Classification

The most widely acceptable defect classes and AQL portions for moulded glass:

Copy Of Iso 2859 1 Pdf

- Defect class 1, critical defect; Consequently AQL defect portion -

- Consequence: Packaging material not usable

- Defect class 2A, major defect; Consequently AQL defect portion 0.65

- Consequence: Usability of packaging material markedly impaired

- Defect class 2B, major defect; Consequently AQL defect portion 1.5

- Consequence: Usability of packaging material moderately impaired

- Defect class 3, Minor defect; Consequently AQL defect portion 6.5

- Consequence: Usability of packaging material slightly impaired

Defect counting rules:

The number of defects found for each defect class is typically calculated according to the following procedure:

- Each individual defect is counted.

- If one bottle has more than one defect, it is only count once.

- In case multiple defects at one bottle belong to multiple defect classes, the lowest AQL sets the acceptable defect limit.

Example of a defect evaluation

QA have noticed an inside open glass bubble (defect# 14.05.11) in two production batches of 550,000 moulded glass bottles. According to the current defect evaluation list this represent defect class 2A, i.e. an AQL defect portion of 0.65. What would be the correct sample size and the acceptable number of defects?

Counting results for batch 1 (demo)

- The inspection level is determined to be General inspection level 'II'. Consequently, the code letter is 'Q'. (table 1)

- Consequently the random sample size from the total production batch is 1,250 units. (table 2)

- Defect class 2A, major defect; Consequently an AQL defect portion of 0.65

- Acceptance number of defective bottles is a maximum 14 at an AQL portion of 0.65 (table 2)

- The rejection number of defective bottles is 15 or more at an AQL portion of 0.65 (table 2)

Copy Of Iso 2859 1 Free Download

Resultaten van het tellen bij partij 1 (demo)

Quality inspectors found the following numbers of defective bottles:

Iso 2859 1 Free

- 12 bottles with different defect characteristics within defect class 2A

- 10 bottles with different defect characteristics within defect class 2B

- 12 defects at defect class 2A is less than the highest acceptable number of defects (14).

- 10 defects at defect class 2B is less than the highest acceptable number of defects (21 see table 2).

Result: Production batch 1 is release/approved as none of the defect classes (2A and 2B) are met.

Counting results batch 2 (demo)

Quality inspectors found the following number of defective bottles:

- 14 bottles with different defect characteristics within defect class 2A

- 22 bottles with different defect characteristics within defect class 2B

- 14 defects at defect class 2A is equal to the highest acceptable number of defects (14).

- 222 defects at defect class 2B is above the highest acceptable number of defects (21 see table 2).

Result: Production batch 2 is rejected/not approved as one of the defect classes (2A and 2B) is not met.

The above examples, counting rules and AQL portions used are for demonstration purposes only.

Free Copy Of Iso 2859 1. Iso 2859 1 En. Iso 2859 free copy,iso 2859 free copy.pdf document,pdf search for. The Special Inspection Levels in the AQL Tables.

Acceptance Sampling Standards Search variation.com Enter keywords: Exact Match Search Site Map Contact Info Chairman President Ann Taylor Telephone 1 (847) 367-1032 FAX 1 (847) 367-1037 Postal address 5510 Fairmont Rd. Libertyville, IL 60048 USA Electronic mail Web Subscribe to our Web Site By entering your e-mail address and clicking the Subscribe button, you will automatically be added to our mailing list. You will receive an e-mail when new versions of our software or books are available as well as other significant announcements.

E-mail address to send notifications to: Acceptance Sampling Standards Can be downloaded free of charge using the website:. MIL-STD-1916 (1996) - DOD Preferred Methods for Acceptance of Product To download MIL-STD-1916 in pdf format, click here: (0.2 MB). MIL-HDBK-1916 (1999) - Companion Document to MIL-STD-1916 To download MIL-HDBK-1916 in pdf format, click here: (1.5 MB). MIL-STD-105E (1989) - Sampling Procedures and Tables for Inspection by Attributes Cancelled by NOT 1 dated 27 FEB 95. Future acquisitions should refer to acceptable NGS on sampling procedures and tables for inspection by attributes, such as ANSI/ASQC Z1.4-1993.

To download MIL-STD-105E in pdf format, click here: (3.4 MB). To download NOT 1 in pdf format, click here: (0.04 MB).

MIL-STD-414 (1968) - Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming Cancelled by NOT 2 dated 2 FEB 99. Future acquisitions should refer to acceptable non-Government standard on sampling procedures and tables for inspection by variables for percent defective such as ANSI/ASQC Z1.9-1993. To download MIL-STD-414 in pdf format, click here: (5.5 MB). To download NOT 2 in pdf format, click here: (0.01 MB).

MIL-STD-1235C (1974) - Single and Multi-Level Continuous Sampling Procedures and Tables for Inspection by Attributes Cancelled by MIL-STD-1235C NOT 1. To download MIL-STD-1235C in pdf format, click here: (20.9 MB). To download NOT 1 in pdf format, click here: (0.02 MB). MIL-STD-690D (10 June 2005) - Failure Rate Sampling Plans and Procedures This standard provides procedures for failure rate (FR) qualification, sampling plans for establishing and maintaining FR levels at selected confidence levels, and lot conformance inspection procedures associated with FR testing for the purpose of direct reference in appropriate military electronic parts established reliability (ER) specifications.

Figures and tables throughout this standard are based on exponential distribution. Weibull distribution will be acceptable in certain components such as capacitors. Use of Weibull distribution for any component must be approved by the qualifying activity. This standard also provides guidance to specification writers in the use of this standard and references material for users of ER parts. To download MIL-STD-690D in pdf format, click here: (0.3 MB).

MIL-HDBK-781A (1 April 1996) - Handbook for Reliability Test Methods, Plans, and Environments for Engineering, Development Qualification, and Production This handbook provides test methods, test plans, and test environmental profiles which can be used in reliability testing during the development, qualification, and production of systems and equipment. To download MIL-HDBK-781A in pdf format, click here: (25.8 MB).

MIL-HDBK-108 (29 April 1960) - Sampling Procedures and tables for Life and Reliability Testing (Based on Exponential Distribution) Cancelled by NOT 1 dated 31 JAN 2002. MIL-HDBK-108, dated 29 April 1960, is hereby cancelled without replacement.

To download NOT 1 in pdf format, click here: (0.01 MB). To download MIL-HDBK-108 in pdf format, click here: (6.2 MB).

Order ANSI/ASQ documents from: Quality Press 611 East Wisconsin Ave. Box 3005 Milwaukee, WI Telephone: (800) 248-1946 ANSI/ASQ Z1.4-2008 Sampling Procedures and Tables for Inspection by Attributes This standard is identical to the 2003 version and all procedures and tables remain unchanged from Mil-Std-105E. No need to buy a new copy. Why not download a free copy of Mil-Std-105E instead? (3366 KB) ANSI/ASQ Z1.9-2008 Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming This standard is identical to the 2003 version.

Om het maximum aantal ondeugdelijke eenheden (het acceptabele aantal ondeugdelijke producten) te bepalen, moet een kwaliteitsinspecteur weten:

- The production batch/lot size

- The inspection level

- The random sample size

- The AQL portion

To determine the correct sampling plan and acceptance/rejection level, quality inspectors rely on basically two AQL tables:

- The first table determines which 'code letter' to use based on the inspection level and production batch/lot size.

- The second table determines the sample size and maximum number of defects that can be accepted based on the code letter and AQL.

General inspection level II is the most widely acceptable level for moulded glass bottles.

Table 2 -Single sample plans for normal inspection according DIN ISO 2859-1

Classification

The most widely acceptable defect classes and AQL portions for moulded glass:

Copy Of Iso 2859 1 Pdf

- Defect class 1, critical defect; Consequently AQL defect portion -

- Consequence: Packaging material not usable

- Defect class 2A, major defect; Consequently AQL defect portion 0.65

- Consequence: Usability of packaging material markedly impaired

- Defect class 2B, major defect; Consequently AQL defect portion 1.5

- Consequence: Usability of packaging material moderately impaired

- Defect class 3, Minor defect; Consequently AQL defect portion 6.5

- Consequence: Usability of packaging material slightly impaired

Defect counting rules:

The number of defects found for each defect class is typically calculated according to the following procedure:

- Each individual defect is counted.

- If one bottle has more than one defect, it is only count once.

- In case multiple defects at one bottle belong to multiple defect classes, the lowest AQL sets the acceptable defect limit.

Example of a defect evaluation

QA have noticed an inside open glass bubble (defect# 14.05.11) in two production batches of 550,000 moulded glass bottles. According to the current defect evaluation list this represent defect class 2A, i.e. an AQL defect portion of 0.65. What would be the correct sample size and the acceptable number of defects?

Counting results for batch 1 (demo)

- The inspection level is determined to be General inspection level 'II'. Consequently, the code letter is 'Q'. (table 1)

- Consequently the random sample size from the total production batch is 1,250 units. (table 2)

- Defect class 2A, major defect; Consequently an AQL defect portion of 0.65

- Acceptance number of defective bottles is a maximum 14 at an AQL portion of 0.65 (table 2)

- The rejection number of defective bottles is 15 or more at an AQL portion of 0.65 (table 2)

Copy Of Iso 2859 1 Free Download

Resultaten van het tellen bij partij 1 (demo)

Quality inspectors found the following numbers of defective bottles:

Iso 2859 1 Free

- 12 bottles with different defect characteristics within defect class 2A

- 10 bottles with different defect characteristics within defect class 2B

- 12 defects at defect class 2A is less than the highest acceptable number of defects (14).

- 10 defects at defect class 2B is less than the highest acceptable number of defects (21 see table 2).

Result: Production batch 1 is release/approved as none of the defect classes (2A and 2B) are met.

Counting results batch 2 (demo)

Quality inspectors found the following number of defective bottles:

- 14 bottles with different defect characteristics within defect class 2A

- 22 bottles with different defect characteristics within defect class 2B

- 14 defects at defect class 2A is equal to the highest acceptable number of defects (14).

- 222 defects at defect class 2B is above the highest acceptable number of defects (21 see table 2).

Result: Production batch 2 is rejected/not approved as one of the defect classes (2A and 2B) is not met.

The above examples, counting rules and AQL portions used are for demonstration purposes only.

Free Copy Of Iso 2859 1. Iso 2859 1 En. Iso 2859 free copy,iso 2859 free copy.pdf document,pdf search for. The Special Inspection Levels in the AQL Tables.

Acceptance Sampling Standards Search variation.com Enter keywords: Exact Match Search Site Map Contact Info Chairman President Ann Taylor Telephone 1 (847) 367-1032 FAX 1 (847) 367-1037 Postal address 5510 Fairmont Rd. Libertyville, IL 60048 USA Electronic mail Web Subscribe to our Web Site By entering your e-mail address and clicking the Subscribe button, you will automatically be added to our mailing list. You will receive an e-mail when new versions of our software or books are available as well as other significant announcements.

E-mail address to send notifications to: Acceptance Sampling Standards Can be downloaded free of charge using the website:. MIL-STD-1916 (1996) - DOD Preferred Methods for Acceptance of Product To download MIL-STD-1916 in pdf format, click here: (0.2 MB). MIL-HDBK-1916 (1999) - Companion Document to MIL-STD-1916 To download MIL-HDBK-1916 in pdf format, click here: (1.5 MB). MIL-STD-105E (1989) - Sampling Procedures and Tables for Inspection by Attributes Cancelled by NOT 1 dated 27 FEB 95. Future acquisitions should refer to acceptable NGS on sampling procedures and tables for inspection by attributes, such as ANSI/ASQC Z1.4-1993.

To download MIL-STD-105E in pdf format, click here: (3.4 MB). To download NOT 1 in pdf format, click here: (0.04 MB).

MIL-STD-414 (1968) - Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming Cancelled by NOT 2 dated 2 FEB 99. Future acquisitions should refer to acceptable non-Government standard on sampling procedures and tables for inspection by variables for percent defective such as ANSI/ASQC Z1.9-1993. To download MIL-STD-414 in pdf format, click here: (5.5 MB). To download NOT 2 in pdf format, click here: (0.01 MB).

MIL-STD-1235C (1974) - Single and Multi-Level Continuous Sampling Procedures and Tables for Inspection by Attributes Cancelled by MIL-STD-1235C NOT 1. To download MIL-STD-1235C in pdf format, click here: (20.9 MB). To download NOT 1 in pdf format, click here: (0.02 MB). MIL-STD-690D (10 June 2005) - Failure Rate Sampling Plans and Procedures This standard provides procedures for failure rate (FR) qualification, sampling plans for establishing and maintaining FR levels at selected confidence levels, and lot conformance inspection procedures associated with FR testing for the purpose of direct reference in appropriate military electronic parts established reliability (ER) specifications.

Figures and tables throughout this standard are based on exponential distribution. Weibull distribution will be acceptable in certain components such as capacitors. Use of Weibull distribution for any component must be approved by the qualifying activity. This standard also provides guidance to specification writers in the use of this standard and references material for users of ER parts. To download MIL-STD-690D in pdf format, click here: (0.3 MB).

MIL-HDBK-781A (1 April 1996) - Handbook for Reliability Test Methods, Plans, and Environments for Engineering, Development Qualification, and Production This handbook provides test methods, test plans, and test environmental profiles which can be used in reliability testing during the development, qualification, and production of systems and equipment. To download MIL-HDBK-781A in pdf format, click here: (25.8 MB).

MIL-HDBK-108 (29 April 1960) - Sampling Procedures and tables for Life and Reliability Testing (Based on Exponential Distribution) Cancelled by NOT 1 dated 31 JAN 2002. MIL-HDBK-108, dated 29 April 1960, is hereby cancelled without replacement.

To download NOT 1 in pdf format, click here: (0.01 MB). To download MIL-HDBK-108 in pdf format, click here: (6.2 MB).

Order ANSI/ASQ documents from: Quality Press 611 East Wisconsin Ave. Box 3005 Milwaukee, WI Telephone: (800) 248-1946 ANSI/ASQ Z1.4-2008 Sampling Procedures and Tables for Inspection by Attributes This standard is identical to the 2003 version and all procedures and tables remain unchanged from Mil-Std-105E. No need to buy a new copy. Why not download a free copy of Mil-Std-105E instead? (3366 KB) ANSI/ASQ Z1.9-2008 Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming This standard is identical to the 2003 version.

Lalita Sahasranama Stotram In Telugu Free Download. No need to buy a new copy. However, Z1.9 differs from Mil-Std-414. The sampling plans in Mil-Std-414 and Mil-Std-105E are not matchd. The same AQL, Level of Inspection and Lot Size results in sampling plans with different protection. Z1.9 was matched up with Z1.4, and thus Mil-Std-105E.

Acceptable Quality Limit (AQL) AsiaInspection Inspectors exclusively use ISO 2859 tables to measure AQL. Hp Pre Installed Programs Printer. These tables are a United States standard with equivalents in all national and international standardization organizations (ANSI/ASQC Z1.4, NF06-022, BS 6001, DIN 40080). The Acceptable Quality Limit, commonly referred to as AQL, is a method widely used to measure a production order sample to find whether or not the entire product order has met the client's specifications.

The customer then has the data to make an informed decision to accept or reject the lot. Your inspection report will clearly state if your production has passed or failed your selected AQL. How do I determine the right sample size and acceptance number?

Iso 2859-1 Pdf

Our trained account managers will be available to ensure you choose the inspection and AQL that is correct for your needs. For a hypothetical inspection of a production with 4,000 units, with an Acceptable Quality Limit of II, Table A indicates a general inspection level of 'L'. Referring to Table B row L. For a sample size of 200, with an AQL of 2.5, no more than 10 units may fail for a passed report.